By K. Richard Douglas

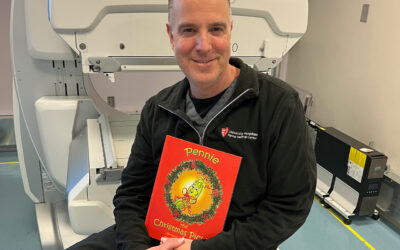

Medical Imaging Equipment Tech II Timothy O’Hara services a GE Healthcare Optima NM/CT 640 nuclear imaging machine.

Academic teaching hospitals play a special role in health care. They are more likely to be level 1 trauma centers, more likely to have pediatric ICUs and more likely to have burn care units. They provide a significant portion of hospital charity care.

When the topic of academic teaching hospitals comes up, the first thought of many are the hospitals in the northeast, like Georgetown or Harvard. Indeed, one of the nation’s best is in Birmingham, Alabama.

The University of Alabama at Birmingham (UAB) Health System is a top-ranked teaching hospital. It is a part of the University of Alabama School of Medicine.

Established in 1945, UAB Hospital is the centerpiece of the UAB Health System.

“The clinical engineering staff at UAB Health System is a part of the physics and engineering group in the department of radiology. We have nine physicists, six service engineers, and two quality control staff. Our service engineers and quality control staff have a combined 175 years of experience maintaining radiology imaging equipment. All are dedicated to radiology imaging,” says Johnny Watkins, chief equipment engineer in the department of radiology.

The imaging team services most equipment including diagnostic X-ray, CT, PET/CT, MRI, PET/MRI, vascular imaging, nuclear medicine, ultrasound and mammography.

“The overall scope of our department includes assistance in the selection of new equipment, planning and installation, physicist surveys of new equipment installed and maintenance during the life of the equipment,” Watkins says.

“Biomed and imaging use the same administrative resources, but are free-standing,” he adds.

Watkins says that his group supports 1,157 beds and that the hospital is one of the 20 largest hospitals in the U.S. and the third-largest public hospital in the U.S.

“Our equipment includes 11 MRIs, one PET/MRI, 16 CT systems, two PET/CT systems, 12 nuclear medicine systems, 38 radiographic and fluoro rooms, 10 mammography systems, 17 vascular labs, 18 portable X-ray units and 34 C-arms. We support and manage all facilities except the Kirklin Clinic at Acton Road,” Watkins says.

“We are OEM-trained in all modalities and operate on the model of ‘first call’ within the major modalities. Smaller equipment, such as C-arms; we go ‘at risk.’ We have no equipment managed 100 percent by the OEM,” Watkins says.

He says that the only equipment they do not service is oncology/therapy equipment because they have their own physicist and make decisions independently.

Training is a key element of the department’s preparation.

“For the major modalities, we receive training from the OEM in their training facilities. It is, however, becoming more popular to have onsite training if possible,” Watkins says.

“Imaging equipment purchasing decisions are made collectively by our team leaders within the modality. This includes technologists, service engineers, physicists and administration. Physics and engineering do play a large role in planning and construction. We also have construction engineers within UAB that facilitate most large projects; also, a collective effort,” Watkins says.

“As the chief engineer, I work closely with our department for sourcing and procurements to negotiate service contracts. Most of the parts we use are covered by service contract but I do source parts and have several third-party vendors I work with locally. Most user training is done by the manufacturer,” he adds.

Improving the Budget with Internal Resources

The team has focused on metrics that improve the patient experience and look for any weak links.

“Within the last couple of years, we have been focused beyond the statistics of looking at numbers for equipment downtime and repair time. As in-house engineers, we can take a deeper look at how the particular downtime affected our patients. For example, was the patient moved to another room? Was the exam canceled? Was contrast used? Answering these questions can tell us if another imaging system is justified or a different back-up plan is needed,” Watkins says.

He says that they also monitor and log each service call by the type of failure the system experienced.

“Was it a software problem, mechanical trouble, defective component or maybe user error? We find monitoring these failure trends increases awareness we would not normally see in the larger scheme of things,” he adds.

The team has also done its share to improve the bottom line and make the best use of resources.

“Getting the most use from our equipment solves a lot of problems within our department and financially for the UAB Health System. Refurbishing older equipment to a quality standard, and making sure everything is updated to manufacturers’ specifications, extends the life of equipment,” Watkins says.

He says that as in-house engineers, they have an opportunity to save critical dollars for the institution and perform at a high level with experience and continued training.

“In the past, we’ve been able to completely refurbish portable X-ray systems with new components and skin to a like-new condition. Converting some of our older C-arms, from CRT displays to flat panel, has also made a significant improvement in image quality to extend the life for a few more years. Our department physicists test quality parameters on a yearly basis that helps us maintain a high quality of imaging in every modality. Maintaining this level of image quality certainly reduces the user perception that equipment should be replaced sooner than later,” Watkins says.

Watkins says that the team has also been able to move equipment to different facilities, which solves a lot of financial challenges.

“With so many facilities, there always seems to be an opportunity to replace older equipment with newer technology and in better condition within the institution. When you have a view of all facilities, items like portable X-ray, C-arms, radiographic rooms and ultrasound system re-purposed properly can save significant capital dollars,” Watkins adds.

When it comes to the crème-de-la-crème of America’s hospitals, the UAB health system, its extensive imaging capabilities and top-notch service engineers are hard to beat.