By Glen Allmendinger and Puneet Pandit

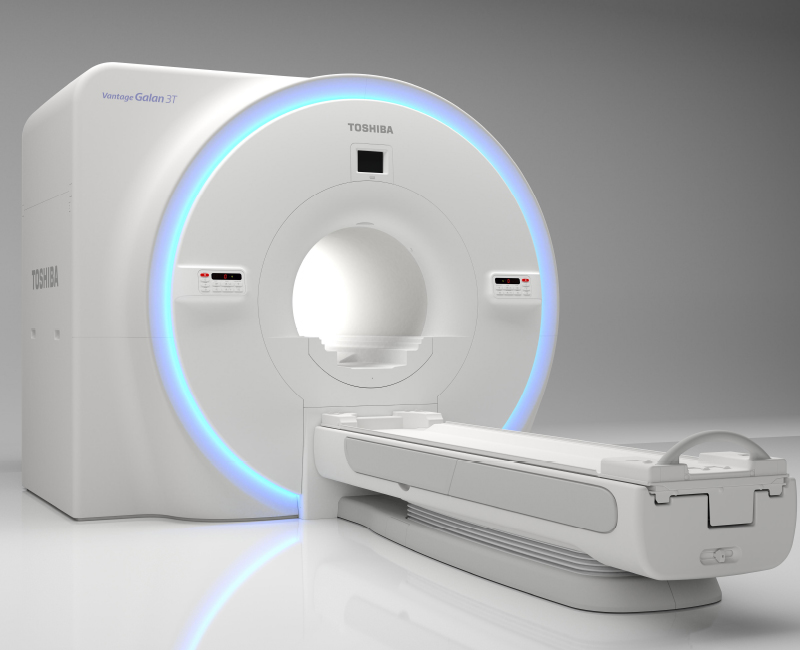

It is not news that health care delivery organizations face enormous challenges. Principal among these is keeping up with advances in capital equipment such as MRI machines and CT scanners. Manufacturers have integrated ever-increasing IoT and Smart Systems technologies into these machines that enable functions such as automated diagnostics, remote patient management and performance monitoring.

Medical professionals and IT teams may view the mountains of data these machines produce as overwhelming. However, with a new generation of analytics incorporating artificial intelligence (AI) and machine learning (ML), these data can become a critical solution for increasing machine uptime, improving patient care and even training of medical staff. Effectively managing complex machine data from health care imaging equipment will produce $11.6 billion of potential revenue value (increased uptime and reduced downtime) by 2022, notes Harbor Research.

Health care Organizations Have 3 Choices

Along with determining which analytics solution health care organizations should deploy comes the question of who will manage the deployment. Today, they have three choices, original equipment manufacturers (OEMs), managing the equipment themselves and independent service organizations (ISOs). Traditionally, OEMs have sold service contracts to manage these complex machines. The obvious advantage is manufacturers know their own equipment in exhaustive detail, but these contracts are often expensive and require parts replacements on a fixed schedule as opposed to when the part actually wears out.

Some health care organizations handle the management of their equipment themselves. This approach allows them to gain first hand, detailed knowledge of their equipment and avoids the costs associated with OEMs. However, these benefits are offset by the need to build and maintain an experienced team that must continuously evaluate equipment performance, often while performing other job functions.

Independent service organizations (ISOs) are companies created specifically to manage health care organizations’ complex equipment. ISOs can draw on knowledge from servicing equipment from multiple vendors and remove the burden of managing equipment away from a health care organization’s internal staff. ISOs typically provide remote monitoring and leverage data to detect anomalies in machine performance that can indicate impending issues.

ISOs are often an attractive alternative for health care organizations. They are typically more flexible in their business models and can tailor their services to the needs of the organization. Their knowledge gained from work with multiple machine vendors gives them a wider breadth of knowledge on which to draw than either OEMs or health care organization teams. And, most ISOs provide remote monitoring, enabling them to detect equipment performance anomalies and either repair these remotely or order replacement parts that arrive at the health care organization before organization staff even realize there is a potential issue.

Better Equipment Management Is Needed

Effective equipment management has become an important topic since a typical MRI machine, for example, can earn $3,500 per hour for a health care facility. Today, the typical machine experiences 8-15 downtime events per year, with an average downtime of 6+ hours. This costs a health care facility $168,000 to $315,000 per year, per machine. For a facility with 10 machines, the numbers jump to $1.68 million to $3.15 million.

Regardless of approach, until recently, a lack of effective data transformation and modeling tools hindered the ability to gain as much knowledge as possible from the data provided by machines. Machine data analytics solutions were not able to handle the range of structured, semi-structured and unstructured data produced by complex equipment. These types of data include:

- Simple: Applications involving simple remote monitoring for maintenance and software upgrades. These include data types such as alerts, alarms and sensor values.

- Compound: These include applications involving complex machines and or multiple peer-to-peer devices and machines that interact. Time series, complex events and simple machine logs are among the data types here.

- Complex: These applications involve multiple parallel peer-to-peer sensors, actuators and complex machines with collaboration and machine learning. Data types such as enterprise data, external data sets and operational data are included here.

Most analytics solutions have been able to process only simple data applications. As a result, they failed to maximize the uptime of their equipment and minimize costs since their analytics did not generate the predictive and prescriptive insights necessary.

New Solutions Bring New Opportunities

New analytics solutions with greatly enhanced capabilities have emerged that dramatically change the game. They are able to convert multiple data types into significantly deeper insights than earlier solutions that not only alert biomeds to an issue, but predict specific performance issues and prescribe recommended solutions.

As health care organizations evaluate these solutions, among the qualities they should seek out include:

- Ability to ingest, parse and analyze multi-structured, complex log data.

- Much faster time to deployment, which reduces costs and generates benefits sooner.

- More granular development of rules and alerts when compared to previous solutions.

- Integration of multiple data types to enable increasingly complex applications.

- Enablement of machine learning and predictive analytics on complex data.

- Ease of use for multiple user personas with different data needs.

With these capabilities, health care organizations can more effectively, accurately and rapidly mine machine data for anomalies, bring structure to unstructured data, manage equipment proactively versus reactively, predict customer needs and trends, and increase customer satisfaction and retention.

A comparison of traditional and new analytics capabilities highlights the leap in performance:

| Traditional Analytics | Next Generation Analytics | |

| Cost | OEM service contracts that can total $150,000 – $200,000 for each machine | Per seat subscription revenue model |

| Use Cases Enabled | Simple asset monitoring: Reactionary maintenance based on after-the-fact reporting | Predictive and preventive maintenance: Performance anomalies trigger alerts of potential failures

Environmental monitoring: Analytics of proper room temperature |

| Assets Monitored | Complex Machines: Primary CTs and MRI machines | Complex Machines: CTs, MRI machines, nuclear medicine equipment, mammography equipment, linear accelerators, infusion pumps, patient monitoring systems |

| Speed to Insights | Days: Faxes sent with asset health information and reactive alerts | Seconds: Automated and customizable “rules and alerts” engine notifies maintenance team, often before a disruption occurs. |

This superior performance creates new, concrete opportunities for ISOs to build their businesses. Remote monitoring capabilities enable ISOs to retain existing health care organization customers and offer “security as a service” versus the vastly more expensive need to secure new customers. It also allows ISOs to become the health care organization’s first line support staff with complete access to a unified machine maintenance record. Advanced data management and analytics encourage ISOs to shift their business models away from reactive, transactional services toward a more predictive manage services model. Improved insights also create opportunities for ISOs to sell in additional services to health care organizations, such as managing their spare parts inventory and service delivery chain.

The health care industry has earned a reputation of operating behind the curve when it comes to the adoption of AI and machine learning to gain ongoing performance improvement and cost reductions. Today’s advanced analytics deployed aggressively by ISOs is rapidly closing this gap and helping health care organizations reap a $11.6 billion market opportunity.

– Glen Allmendinger is the president and founder of Harbor Research. Puneet Pandit is the founder and CEO of Glassbeam Inc.